Auto-electrical and electronic

components manufacturer

At FAE we manufacture electrical and electronic components for the automotive sector, with a range of more than 5,000 references with OEM quality. We combine the most advanced technologies with an excellent team of professionals, to obtain solutions of the highest quality and adapted to specific requirements. of each client.

75% of export sales

Present in more

from 100 countries

Only the perfect combination of human resources and technology can offer innovative and quality solutions at a competitive price. At FAE we have consolidated our position in the field of multilayer ceramic application design, development of ceramic substrates and implementation of microelectronic systems.

Explore our range of products

Together SINCE 1952

FAE celebrates 70 years

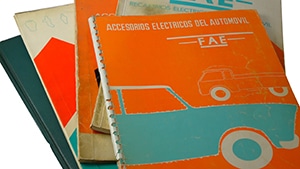

In 1952 Francisco Albero and Rosa Llovensa, my grandparents, had a mechanical workshop in Barcelona. As most workshops were dedicated to replacing damaged components but over time, they realized that they could repair the parts they replaced, leave them as new and sell them to the aftermarket.

They had a small cubicle in the back of the workshop where they could fix the pieces between clients. The demand was growing until a time came when they decided to start manufacturing their own pieces. The drawing room was his living room and the factory was his back room. Soon they closed the workshop to be able to dedicate all their efforts to serving the new business. He would design, manufacture and go out to sell the pieces in a van while she would take the numbers of the company and receive the clients. But the most important thing was missing, the name. In this way a small company called FAE was founded.

Read the complete news here.

FAE launches the first AFR Oxygen Sensor and the new parking sensors

FAE launches the new COX7 Oxygen Sensors catalog with 47 references from the new Air Fuel Ratio family with 16.5 million applications.

FAE launches the new COX7 Oxygen Sensors catalog with 47 references from the new Air Fuel Ratio family with 16.5 million applications.

FAE entra a formar parte de la lista de Preferred Supplier con el grupo de compra Nexus Automotive International.

Sponsor Team 77 team, offers its SAT service in LATAM

- FAE comienza a esponsorizar al equipo Team 77 que lidera Pep Mas y que participa en el Rally DAKAR 2020 en Perú. Anselm Moya, del CENTRO TÉCNICO MÓVIL – CTM de FAE, da cobertura al piloto durante la carrera. Estas competiciones tan extremas representan un excelente banco de pruebas para los productos FAE.

- FAE offers its Technical Assistance Service in LATAM. Since the beginning of March 2020, FAE has made its Technical Assistance Service, SAT, available to its LATAM clients.

New ESD room, start of SAT service, agreement with Nexus, development of AIR FUEL RATIO A/F

FAE puts into operation the 180m2 ESD room with dissipative floor dedicated exclusively to manufacturing Absolute Pressure Sensors (MAP), Exhaust Gas Pressure Sensors (EGPS) and Gear Position Sensor (GPS), with a manufacturing capacity of 500,000 units /year per shift.

FAE begins to offer the TECHNICAL ASSISTANCE SERVICE – TAS to its clients in Spain. With this service, all queries that may arise about FAE products are answered, such as warranty management, identification, assembly and operation of parts.

Start of the development of the AIR FUEL RATIO A/F Lambda Sensors technology.

Recognised as a “Surprising Brand”, presents its MTC, has joined ATR, certified IATF 16949

FAE, chosen as “Brand That Surprising” in Oxygen Sensors in the framework of the “Quality and Service Awards in Automotive Aftermarket” held in Spain at the beginning of 2018.

FAE presents its MOBILE TECHNICAL CENTER – MTC. Pioneer and innovator in Spain by working with this mobile technical assistance system. The MTC has three main and fundamental objectives:

- Visit workshops and offer them technical advice

- Offer training and advice to our distributors

- Provide continuous training to workshops

FAE signs with the ATR International AG group as a new recognized supplier with a general international agreement, giving it the opportunity to explore new markets and grow together with the group.

FAE obtains the IATF 16949. In 2018, the company was certified according to the IATF 16949-2016 standard as the completion of the transition process from the ISO/TS 16949:2009 automotive standard to the new IATF 16949:2016 benchmark.

Inauguration of Clean Room, new sales strategy in the NAFTA market, Joint Venture FAE – LUMAX and Solenoid valves

Clean Room type ISO-7 of 700m2 dedicated exclusively to the production of ceramic sensors (Oxygen Sensors) for the automotive sector.

Collaboration with Atlantic IM & Export Corporation to represent FAE in the NAFTA market against the distributor.

Joint Venture Lumax FAE Technologies Pvt. LTD with a capacity of 2 million lambda probes per year.

New adjoining building and facilities of 2,500m² (total 15,000m²)

Offices dedicated to OEM and HR.

Increased storage capacity to provide better customer service.

OEM department creation

Creation of a team dedicated exclusively to OEMs to provide quality service to our customers.

Business strategy of focusing on OEM to continue growing.

Plastic injection factory, new assembly workshop, ABS sensors

New 5,000m2 supplier park in Cervera, with 2 assembly workshops and a plastic injection factory.

Creation of videos to help with the assembly of FAE products in the workshop, available on the web and YouTube.

New family of products, the Wheel Revolution Sensors (ABS).

New family of Exhaust Gas Pressure Sensors – EGPS

Expanding our catalogue, FAE creates the new family of Exhaust Gas Pressure Sensors – EGPS.

ISO TS 16949:2009

FAE obtains the ISO TS 16949:2009 certificate, continuing our commitment to quality and service.

Expansion to 12,000m2

With the new extension, FAE enlarges the engineering department, the clean room, the electronics room and the raw material warehouse.

New electronics room, first MAP and ZR Oxygen Sensor, ISO 14001:2004

FAE obtains the ISO 14001:2004 certificate that demonstrates our commitment to the environment.

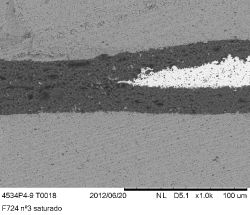

The first Zirconium Oxygen Sensor with planar technology and the first MAP Sensor are manufactured.

Ceramic and nanofiber technology

FAE begins to develop multilayer ceramic technology and to investigate carbon nanofibers.

First Revolution and Timing Sensors and Titanium Oxygen Sensor

The first Titanium Oxygen Sensor is manufactured.

FAE manufactures the first Revolution and Timing Sensors, the first electronic product of the FAE families.

Department of advanced materials

The department of advanced materials is created and the construction of a Clean Room of 250m2.

Start of development of Oxygen Sensors

FAE begins the development of the Oxygen Sensors together with the collaboration of the University of Barcelona.

ISO 9001:1994

FAE is a pioneer in the automotive spare parts sector in Spain in obtaining the ISO 9001:1994 certificate, which ensures our production process.

New 3,500m2 factory

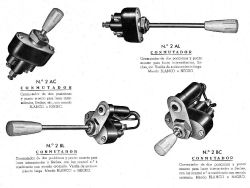

FAE inaugurates a new factory of 3,500m2, and what will be the main guidelines of the company are marked, specializing in panel switches, motor, Pressure and Temperature Sensors.

Start of sales to first teams

For the first time, FAE supplies car manufacturers located in Spain, such as Authi-Mini, Chrysler trucks (Talbot), Enasa, Motor Ibérica, Pegaso, Bultaco, Derbi and Sanglas.

FAE starts the export

FAE participates for the first time in an automobile spare parts fair in France.

Foundation of FAE, Francisco Albero Electricity

Fundación de FAE. The first Pressure Switch is manufactured, marking the beginning of a wide range of electrical spare parts for the automobile sector.