Definition and operation of EGTS (exhaust gas temperature sensor)

The EGTS detects exhaust gas temperature, converts it into a voltage, and sends that voltage signal to the engine control unit (ECU) to monitor engine conditions and effectively reduce emissions.

In petrol engines, if the sensor detects excessive temperatures, the ECU will reduce the temperature by lowering the boost pressure. In diesel engines, the sensor is used to monitor the temperature of the diesel particulate fi lter (DPF) to determine the exact temperature for regeneration.

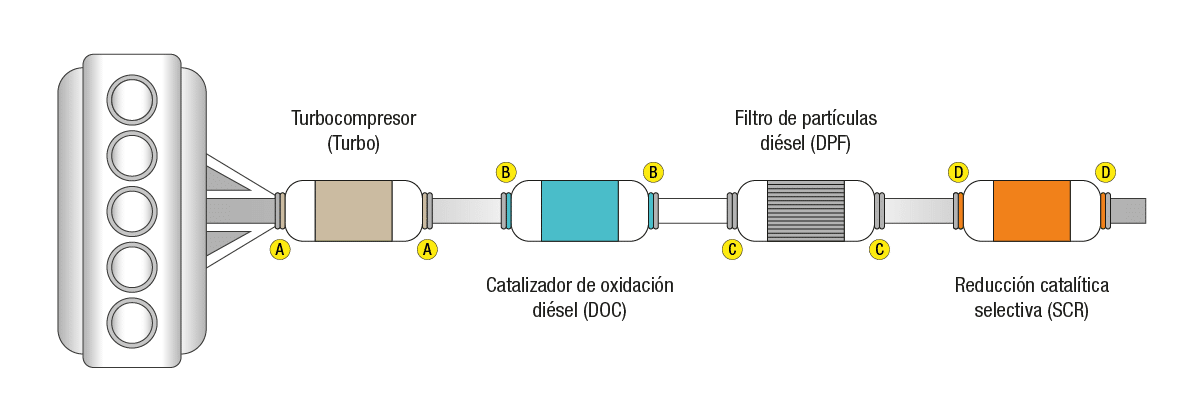

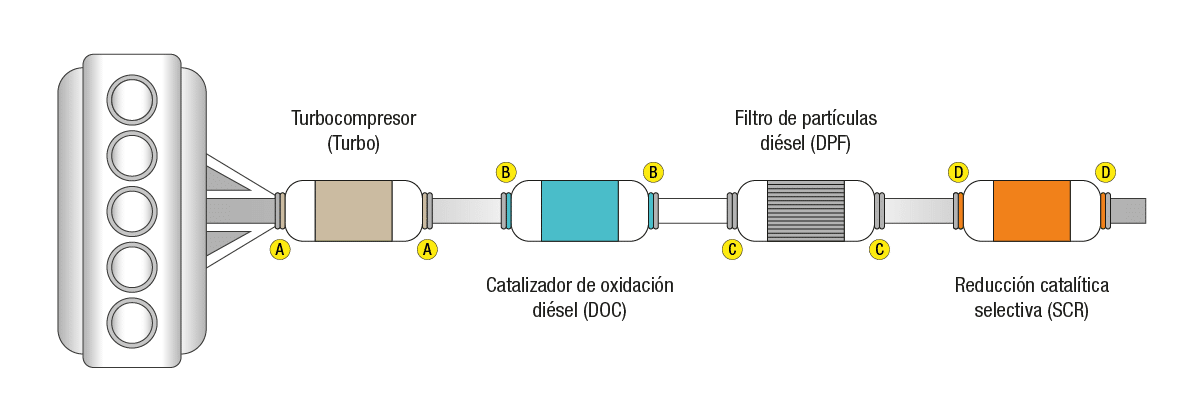

Where is the EGTS located inside the vehicle?

Exhaust gas temperature sensors can be found at multiple points in the vehicle’s exhaust system. As they’re used to monitor exhaust gas temperatures and protect critical systems from overheating or failure, these sensors are generally located near these critical system components. For example, one or more EGT sensors may be located near the EGR valve, turbocharger and diesel particulate filter to ensure proper system effi ciency.

A – Before and after the turbocharger (Turbo)

The EGT sensor fi tted around the turbocharger verifi es that the component temperature has dropped to around 150°C to 200°C for proper operation, while also monitoring the temperature of the component for overheating.

B – Before and after the diesel oxidation catalyst (DOC)

The EGT sensor fi tted around the diesel oxidation catalyst (DOC) is to monitor the inlet exhaust temperature, with a minimum temperature of 200°C required for operation. It also monitors the health of the component, such as for DOC clogging or overheating.

C – Before and after the diesel particulate filter (DPF)

The EGT sensor fitted around the diesel particulate filter (DPF) verifies es the DPF regeneration process is complete and effective. It also monitors the health of the component, such as for DPF clogging or overheating.

D – Before and after selective catalytic reduction (SCR)

The EGT sensor fitted around the selective catalytic reduction (SCR) monitors the temperature of the inlet exhaust, which requires a temperature of around 200°C to 400°C to start working, and that the outlet exhaust has been properly treated.